Alloy Steel Fasteners Manufacturers and Exporters

ASTM A194 Alloy Steel Hexagon Nuts, Alloy Steel U Bolts, Alloy Steel Stud, Alloy Steel Washers Suppliers in India.

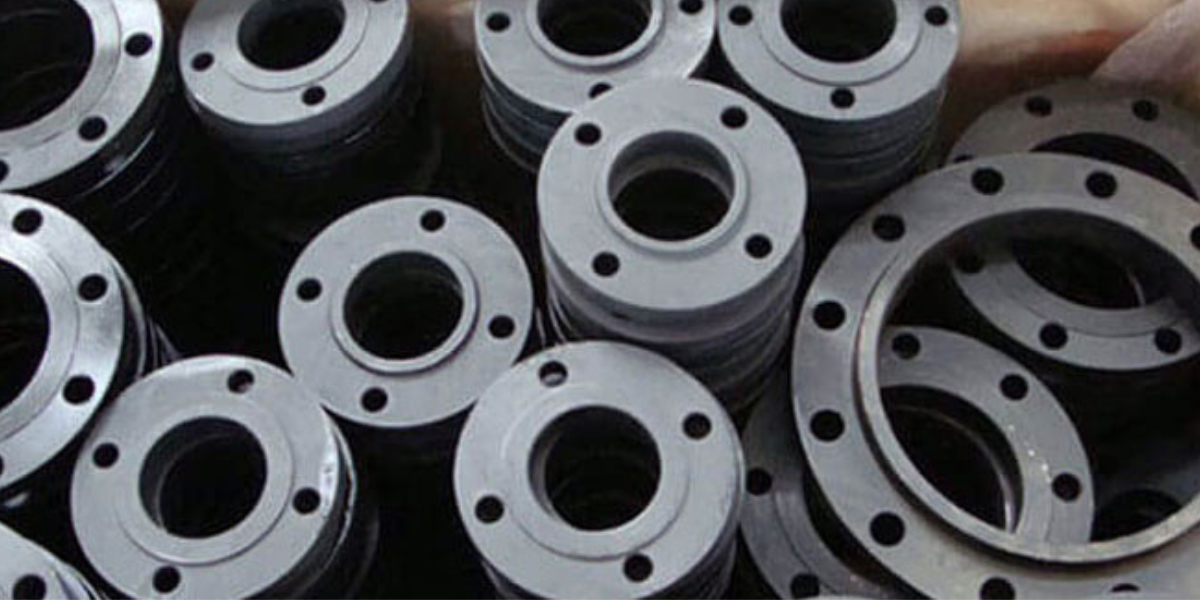

These Alloy Steel fasteners can be provided by us in different finish sizes along with in uninterrupted construction finish so as to perfectly match in the company of the precise progression demands of the customers. Available in different specifications, a great number of different industries find these fasteners use in chemical industry, boiler machinery, oil industry, electric power, and so on. Our ability also lies in meeting the needs of other non-standard sizes as required by the customers. These fasteners can be provided by us in different finish sizes along with in uninterrupted construction finish so as to perfectly match in the company of the precise progression demands of the customers. Available in different specifications, a great number of different industries find these fasteners use in chemical industry, boiler machinery, oil industry, electric power, and so on. Our ability also lies in meeting the needs of other non-standard sizes as required by the customers. These products are having some excellent features like Long functional life, Sturdy construction, Optimum performance, and so on. Our AS Fasteners are accessible to our valuable customers in different range of diameters, wall thicknesses and sizes at quite affordable rates.

Features of Alloy Steel Fasteners :-

| High strength | Resistance against corrosion |

| Resistance against High pressure | Resistance against High temperature |

| Resistance against Dimensions stability | Longer service life |

| Resistance against High mechanical stress | |

ASTM A387 Alloy Steel Fasteners Specification:-

Standards : DIN, ASTM, BS and all International Standards

Specifications : ASTM / ASME A/SA 193 / 194

Size : M02 to M33

Length : UPTO 5 METERS

Grade : B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M

Type : Nuts, Screw, Bolts, Sockets, Studs, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U- Bolts, J Bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, Structural Bolts.

Our Alloy Steel Fasteners conforms to NACE MR0175/ISO 15156

Other Products of Alloy Steel Sheet / Plate / Coil

• ASTM A387 Alloy Steel Plates

• Alloy Steel Coils

• AS Perforated Sheet

• ASTM A387 Alloy Steel Chequered Plate

• Alloy Steel A387 Rolls

• Alloy Steel Ring

• ASTM A387 Alloy Steel Shim Sheet

• Alloy Steel A387 Strips

• Alloy Steel A387 Flat

• Alloy Steel Blank

• Alloy Steel Profile

• ASTM A387 Alloy Steel Foils

Types Of Available Products AISI, ASTM, DIN, JIS, GB, EN Alloy Steel Fasteners

Alloy Steel A194 Nuts

Alloy Steel B 7 Washers

ASTM A193 Alloy Steel U Bolts

A193 AS Allen Cap Screw Suppliers

ASTM A194 Alloy Steel Screw Manufacturer

A194 AS Threaded Rods Manufacturer

ASTM A193 Alloy Steel Threaded Stud

AS Structural Bolts Stockiest in India

Alloy Steel Hexagon Nut Stockholder

ASTM A193 Alloy Steel Foundation Bolts

Alloy Steel Machine Screws Distributors

A194 Alloy Steel Hex Domed Cap Nuts

Top Quality Alloy Steel Spring Washers

Alloy Steel Hex Head Bolts Exporter

Alloy Steel Fasteners: High-Performance Connecting Elements for Critical Industrial Applications

In the demanding landscape of industrial assembly and construction, alloy steel fasteners represent the essential components that hold complex structures and machinery together under extreme operational conditions. These precision-engineered elements provide the clamping force, structural integrity, and reliability required in applications where failure could result in catastrophic consequences. Arham Alloys has established itself as a leading manufacturer and exporter of premium alloy steel fasteners, delivering products that combine superior metallurgical properties with exacting dimensional accuracy to serve industries worldwide.

Metallurgical Engineering: The Science Behind Superior Fastener Performance

Alloy steel fasteners achieve their exceptional properties through carefully controlled chemical compositions where strategic alloying elements enhance strength, toughness, and environmental resistance. The incorporation of chromium provides corrosion resistance and hardenability, while molybdenum enhances high-temperature strength and resistance to creep deformation. Nickel additions improve toughness, particularly at low temperatures, and vanadium creates stable carbide precipitates that strengthen the material through precipitation hardening mechanisms.

The ASTM A194 specification governs the production of alloy steel fasteners intended for high-temperature and high-pressure service, establishing stringent requirements for chemical composition, mechanical properties, and dimensional tolerances. These standards ensure that fasteners perform reliably in demanding applications including pressure vessels, power generation equipment, petrochemical processing facilities, and other critical installations where component failure would threaten personnel safety, environmental integrity, and operational continuity.

Comprehensive Product Portfolio: Nuts, Bolts, Studs, and Specialized Components

Hexagon nuts manufactured from alloy steel fasteners materials provide secure threaded connections capable of withstanding substantial tensile loads and vibration stresses. The six-sided configuration enables efficient installation and removal using standard tools while providing multiple bearing surfaces that distribute clamping forces uniformly. Heavy hex nuts offer increased bearing area and thickness for applications involving large-diameter bolts or extreme loading conditions where standard hex nuts would be insufficient.

U-bolts fabricated from alloy steel fasteners stock secure pipes, cables, and equipment to structural supports while accommodating thermal expansion and operational vibration. The curved configuration wraps around cylindrical components, with threaded legs passing through mounting brackets secured by nuts. The superior strength and fatigue resistance of alloy steel enables these fasteners to maintain clamping force throughout years of service despite repeated stress cycling and environmental exposure.

Studs represent another critical category of alloy steel fasteners, providing threaded connecting elements for applications where through-bolts are impractical or where one end must remain permanently installed. Double-ended studs with threads on both ends facilitate connections between flanges, pressure vessel closures, and machinery assemblies. Tap-end studs with one threaded end for permanent installation and one end with run-out threads for nut engagement prove ideal for equipment requiring frequent disassembly for maintenance or inspection.

Washer Solutions: Distributing Loads and Protecting Surfaces

Washers manufactured from alloy steel fasteners materials serve multiple critical functions in bolted assemblies. Flat washers distribute clamping loads over larger bearing areas, preventing fastener heads and nuts from damaging softer substrate materials or pulling through thin-walled components. The increased bearing area reduces contact stresses that could cause localized yielding or embedment of fastener components into assembled parts.

Lock washers provide mechanical resistance against loosening caused by vibration, thermal cycling, or operational stresses. Split lock washers create spring tension that maintains bolt preload despite minor settling or relaxation of bolted joints. Toothed lock washers with serrated edges bite into bearing surfaces, creating friction that prevents rotation of nuts or bolt heads. The superior strength and spring characteristics of alloy steel fasteners enable lock washers to maintain effective locking force throughout extended service periods.

Grade Selection: Matching Material Properties to Application Requirements

The diverse range of alloy steel fasteners grades available enables precise matching of material properties to specific service conditions and performance requirements. Grade 2H fasteners provide basic alloy steel properties suitable for moderate-temperature applications up to 750°F. Grade 4 offers enhanced strength for applications involving higher stresses or temperatures reaching 1000°F. Grade 7 and Grade 7M provide the highest strength levels with temperature capabilities extending to 1100°F, making them ideal for the most demanding high-temperature, high-pressure services.

Low-temperature service applications require specialized alloy steel fasteners grades that maintain toughness and ductility in cryogenic environments. Nickel-enriched alloys prevent the ductile-to-brittle transition that renders ordinary steels dangerously fragile in extreme cold. These specialized fasteners prove essential in liquefied natural gas facilities, cryogenic storage systems, and industrial gas production plants where temperatures plunge far below zero.

Surface Treatments and Protective Coatings

While alloy steel fasteners possess inherent corrosion resistance from alloying elements, additional surface treatments can further enhance environmental durability and functional performance. Zinc plating provides economical corrosion protection for fasteners in moderately corrosive environments, creating a sacrificial barrier that corrodes preferentially to protect the underlying steel. The bright, attractive finish also facilitates visual inspection and inventory management.

Hot-dip galvanizing applies thick zinc coatings that deliver extended corrosion protection in harsh outdoor exposures and industrial atmospheres. The metallurgical bond between zinc and steel substrate creates durable coatings that resist chipping and mechanical damage during handling and installation. Phosphate coatings provide corrosion protection while improving paint adhesion and reducing friction during installation, enabling more accurate torque-tension relationships in critical bolted joints.

Threading Standards and Dimensional Accuracy

Thread geometry represents a critical parameter governing the performance and interchangeability of alloy steel fasteners. Unified National Coarse (UNC) and Unified National Fine (UNF) thread forms dominate North American applications, while metric thread standards prevail in international markets. The choice between coarse and fine threads involves trade-offs between assembly speed, thread strength, and resistance to vibration loosening.

Precision thread manufacturing ensures that alloy steel fasteners achieve proper fit with mating components while developing full thread strength. Class 2A tolerances for external threads and Class 2B tolerances for internal threads provide standard fits with slight clearance for easy assembly despite minor contamination or surface finish variations. Class 3A and 3B tolerances specify tighter fits for applications demanding maximum thread engagement and load distribution.

Heat Treatment Processes: Optimizing Mechanical Properties

Quenching and tempering operations transform alloy steel fasteners from soft, machinable stock into high-strength components capable of withstanding extreme service loads. Austenitizing at elevated temperatures dissolves carbides and homogenizes the microstructure before rapid cooling through quenching creates a hard, martensitic structure. Subsequent tempering at controlled temperatures reduces brittleness while maintaining high strength, achieving optimal combinations of hardness, strength, and toughness.

Stress relieving heat treatments eliminate residual stresses introduced during cold forming, machining, or welding operations. These thermal cycles prevent distortion, cracking, or premature failure of alloy steel fasteners subjected to operational stresses. Carburizing surface treatments diffuse carbon into fastener surfaces, creating wear-resistant cases while maintaining tough, ductile cores. This treatment proves valuable for fasteners experiencing repeated assembly and disassembly cycles that could cause galling or thread damage.

Industrial Applications: Serving Critical Sectors with Reliable Solutions

Chemical processing facilities rely on alloy steel fasteners throughout piping systems, pressure vessels, and reaction equipment handling corrosive chemicals at elevated temperatures and pressures. The combination of strength and corrosion resistance enables safe containment of hazardous materials while withstanding thermal cycling, vibration, and chemical attack. Fastener integrity remains critical as even minor leaks could result in personnel injuries, environmental contamination, or explosive reactions.

Boiler and pressure vessel construction demands alloy steel fasteners capable of maintaining clamping force and structural integrity under sustained high-temperature, high-pressure service. Creep-resistant alloy grades prevent gradual deformation that could loosen joints and compromise sealing effectiveness. The dimensional stability under thermal cycling ensures that bolted flanges maintain proper gasket compression throughout repeated startup and shutdown sequences.

Oil and gas production operations subject alloy steel fasteners to harsh conditions including sour gas environments, high pressures, temperature extremes, and corrosive fluids. Wellhead assemblies, production manifolds, and processing equipment depend on fasteners that resist sulfide stress cracking while maintaining structural integrity. The reliability of these connections directly impacts operational safety, environmental protection, and production continuity in remote locations where maintenance access may be limited.

Power Generation: Supporting Critical Energy Infrastructure

Electric power generation facilities utilize alloy steel fasteners in turbine assemblies, generator components, boiler systems, and auxiliary equipment operating under demanding conditions. Steam turbines subject fasteners to high temperatures, centrifugal forces, and vibrational stresses that test material capabilities. The fatigue resistance and creep strength of properly selected alloy steel enables these fasteners to maintain preload and structural integrity throughout decades of continuous operation.

Nuclear power plants impose the most stringent requirements on alloy steel fasteners, demanding exceptional quality, comprehensive testing, and complete documentation to satisfy regulatory requirements. These applications require materials that resist radiation embrittlement, maintain properties throughout extended high-temperature service, and demonstrate reliable performance in safety-critical systems. The traceability and quality assurance protocols associated with nuclear-grade fasteners set industry standards for manufacturing excellence.

Automotive and Transportation: Enabling High-Performance Vehicles

Automotive manufacturers incorporate alloy steel fasteners in engine assemblies, transmission systems, suspension components, and chassis structures where strength, fatigue resistance, and weight optimization prove critical. Connecting rod bolts must withstand millions of stress cycles at high temperatures without elongating or failing. Cylinder head studs maintain clamping force despite extreme thermal gradients and combustion pressures. The reliability of these fasteners directly affects engine durability and vehicle safety.

Heavy-duty commercial vehicles and off-highway equipment demand alloy steel fasteners capable of withstanding severe loading, vibration, and environmental exposure. Wheel fasteners securing massive tires must resist loosening despite continuous vibration and shock loading from rough terrain. Structural fasteners in equipment frames and boom assemblies bear substantial static and dynamic loads while exposed to dirt, moisture, and temperature extremes. The durability of alloy steel ensures these fasteners maintain integrity throughout demanding service lives.

Aerospace Applications: Meeting Exacting Standards for Flight-Critical Systems

Aircraft construction requires alloy steel fasteners that satisfy stringent strength-to-weight requirements while demonstrating absolute reliability in flight-critical applications. Engine mount fasteners must withstand extreme vibration, thermal cycling, and sustained loads while preventing catastrophic failure. Landing gear assemblies depend on fasteners that absorb tremendous impact loads during touchdown while resisting fatigue throughout countless landing cycles.

Military aerospace applications impose additional requirements for alloy steel fasteners including resistance to extreme temperatures, electromagnetic effects, and ballistic damage. Fighter aircraft subject fasteners to rapid acceleration, aggressive maneuvering loads, and supersonic flight conditions. Helicopter rotor assemblies generate tremendous centrifugal forces and alternating stresses that test fastener capabilities. The quality assurance and testing protocols for aerospace fasteners ensure reliability in applications where failure is not an option.

Custom Manufacturing: Non-Standard Sizes and Special Configurations

While standard alloy steel fasteners dimensions satisfy most industrial requirements, specialized applications often demand custom sizes, configurations, or specifications. Our manufacturing capabilities accommodate non-standard lengths, diameters, thread forms, and head styles tailored to unique customer requirements. This flexibility enables engineers to optimize fastener designs for specific applications without compromising performance through makeshift adaptations of standard components.

Special coatings, marking requirements, or packaging specifications can be implemented to satisfy customer quality systems or installation procedures. Custom alloy steel fasteners for proprietary equipment designs protect intellectual property while ensuring optimal performance. Our engineering team collaborates with customers to develop fastener solutions that balance technical requirements, manufacturing feasibility, and cost effectiveness.

Quality Assurance: Comprehensive Testing and Certification

Rigorous quality control measures ensure that alloy steel fasteners leaving our facilities meet specified performance standards and dimensional requirements. Chemical composition analysis verifies that alloying elements fall within grade specifications. Mechanical property testing includes tensile strength measurement, proof load verification, hardness evaluation, and impact toughness assessment. These tests confirm that fasteners will perform reliably under specified service conditions.

Dimensional inspection protocols verify thread geometry, head dimensions, length tolerances, and surface finish quality. Hardness testing throughout fastener cross-sections ensures that heat treatment processes have achieved uniform properties. Non-destructive examination techniques detect surface and subsurface defects that could initiate premature failures. Complete documentation including material certifications, test reports, and traceability records accompanies shipments, satisfying customer quality requirements and regulatory compliance obligations.

Global Supply Excellence: Mumbai Manufacturing and Export Capabilities

Our strategic position as manufacturers in Mumbai provides excellent access to world-class port facilities, enabling efficient export operations to international markets. The comprehensive industrial infrastructure supports specialized manufacturing processes, advanced testing capabilities, and reliable logistics services. This integrated ecosystem enables us to deliver high-quality alloy steel fasteners on competitive schedules while maintaining cost effectiveness.

The concentration of technical expertise and skilled workforce ensures our operations maintain the highest standards of manufacturing precision and quality control. Whether your application requires standard fasteners in production quantities or custom components for specialized equipment, Arham Alloys delivers the products, expertise, and support that ensure successful outcomes. Contact our technical team to discover how our alloy steel fasteners can enhance your assembly reliability, operational safety, and long-term performance.

Product Usage & Application:-

- Useful in Paper & Pulp Companies

- Useful in High-Pressure Applications

- Useful in Oil and Gas Industry

- Useful in Chemical Refinery

- Useful in Pipeline

- Useful in High-Temperature Application

- Useful in Water Pipe Line

- Useful in Nuclear Power Plants

- Useful in Food Processing and Dairy Industries

- Useful in Boiler & Heat Exchangers

FAQs

1. What are alloy steel fasteners and why are they widely used?

Alloy steel fasteners are high-strength fastening components manufactured using alloy steel that contains additional elements such as chromium, molybdenum, nickel, or vanadium. These elements enhance mechanical properties such as tensile strength, hardness, wear resistance, and corrosion resistance.

Industries prefer alloy steel fasteners because they can withstand extreme pressure, high temperatures, and heavy loads. They are commonly used in construction, oil and gas, automotive, power generation, and heavy engineering applications where standard carbon steel fasteners may not perform adequately.

2. What types of alloy steel fasteners do manufacturers produce?

Leading alloy steel fasteners manufacturers and exporters produce a wide variety of fastening components, including:

- Alloy steel bolts

- Alloy steel nuts

- Alloy steel screws

- Alloy steel washers

- Alloy steel studs

- Threaded rods

These alloy steel fasteners are available in different grades, sizes, coatings, and specifications to meet international standards such as ASTM, DIN, ISO, and ANSI. Custom manufacturing is also available for specialized industrial applications.

3. What industries rely heavily on alloy steel fasteners?

Several critical industries depend on high-quality alloy steel fasteners for structural integrity and safety, including:

- Oil & Gas

- Petrochemical

- Power plants

- Infrastructure & construction

- Automotive & heavy equipment

- Marine & offshore

Because alloy steel fasteners offer superior strength and durability, they are essential in applications involving vibration, pressure, and temperature fluctuations.

4. How do alloy steel fasteners manufacturers ensure product quality?

Reputable alloy steel fasteners manufacturers and exporters follow strict quality control processes at every stage of production. This includes:

- Careful selection of raw materials meeting international composition standards

- Controlled cold-drawing operations

- Precision dimensional checks

- Mechanical testing for tensile strength and hardness

- Surface treatment inspections

At Arham Alloys, state-of-the-art production facilities and stringent quality assurance protocols ensure that every batch of alloy steel fasteners meets global performance and safety standards.

5. What role does raw material selection play in alloy steel fasteners manufacturing?

The quality of alloy steel fasteners begins with raw material selection. Manufacturers choose alloy steel grades that meet specific chemical composition standards to ensure durability and mechanical strength.

At Arham Alloys, the manufacturing process starts with carefully selected raw materials that comply with international standards. This guarantees consistent strength, structural reliability, and long service life in demanding industrial environments.

6. What is the importance of cold-drawing in alloy steel fasteners production?

Cold-drawing is a critical step in the manufacturing of alloy steel fasteners. This process refines the material’s grain structure, improves dimensional accuracy, and enhances tensile properties.

Through controlled cold-drawing operations, manufacturers achieve precise dimensions and mechanical properties required by modern industries. This ensures that the alloy steel fasteners deliver reliable performance under high stress conditions.

7. What delivery states are available for alloy steel fasteners?

Experienced alloy steel fasteners manufacturers and exporters offer products in multiple delivery states to meet different application requirements, including:

- Soft-annealed for easy forming

- Light-drawn for moderate strength applications

- Cold-drawn to specific tensile properties

Arham Alloys provides a comprehensive range of wire diameters and delivery conditions, allowing manufacturers to source all their alloy steel fasteners requirements from a single, dependable supplier.

8. Are alloy steel fasteners customizable?

Yes, most leading alloy steel fasteners manufacturers and exporters provide customization options. This includes:

- Custom sizes and threading

- Specific tensile strength requirements

- Heat treatment processes

- Coatings such as zinc plating, hot-dip galvanizing, or PTFE coating

Customization ensures that alloy steel fasteners meet the precise operational needs of various industries and engineering projects.

9. What international standards do alloy steel fasteners comply with?

High-quality alloy steel fasteners are manufactured in compliance with international standards such as:

- ASTM (American Society for Testing and Materials)

- DIN (Deutsches Institut für Normung)

- ISO (International Organization for Standardization)

- ANSI (American National Standards Institute)

Compliance with these standards ensures consistency, reliability, and compatibility across global markets, making it easier for exporters to supply alloy steel fasteners worldwide.

10. Why choose Arham Alloys as your alloy steel fasteners manufacturer and exporter?

When selecting among alloy steel fasteners manufacturers and exporters, reliability, quality, and technical expertise are key considerations.

Arham Alloys stands out because of:

- State-of-the-art production facilities

- Strict quality assurance protocols

- International-standard raw material sourcing

- Controlled cold-drawing operations

- Multiple delivery states for varied applications

- Comprehensive wire diameter range

With a strong commitment to precision and performance, Arham Alloys ensures that every alloy steel fasteners product meets modern industrial demands while maintaining consistent quality and timely delivery.

We Export To :

Kazakhstan, Algiers, Johannesburg, Pretoria, Dakar, Ghana, Uganda, Mozambique, Iraq, Subra al-Haymah, Australia, Yaoundé, South Africa, Saudi Arabia, Kampala, Benin, Ethiopa, Kuwait, Luanda, Abu Dhabi, Peru, Sudan, Colombia, Nairobi, Turkey, Russia, Khartoum, Kano, UAE, Bahrain, Cape Town, Trinidad and Tobago, Dar es Salaam, Nigeria, Antananarivo, Tripoli, Addis Ababa, London, Douala, Lebanon, Tunisia, Ouagadougou, Mogadishu, Harare, Mbuji-Mayi, Qatar, Zaria, Soweto, Omdurman, Angola, Alexandria, Dubai, Yemen, Casablanca, Africa, Oman, Giza, Kinshasa, Bamako, UK, Houston, Accra, Algeria, Argentina, Cairo, Chine, Kolwezi, Hong Kong, Abidjan, Vietnam, Port Elizabeth, Maputo, Maiduguri, Canada, Port Harcourt, Singapore, Egypt, Venezuela, Freetown, Ibadan, Iran, Fez, Malaysia, Mexico, Cameroon, New York, Indonesia, Italy, Azerbaijan, Israel, Conakry, Brazil, Democratic Republic of the Congo, New Zealand, Morocco, Jordan, United States, Thailand (Bangkok), Cyprus, Sri Lanka, Rabat, Bulawayo, Kaduna, Durban, Colombo, Germany, Lubumbashi, Lagos, Brazzaville.

We Supply To :

Tripura, Ahmedabad, Kolkata, Lucknow, Andhra Pradesh, Pune, Ambala, Maiduguri, Buxar, Puducherry, Karnataka, Maharashtra, Bhiwadi, Surat, Mizoram, Manipur, Delhi, Bangalore, Kerala, Ballia, Jamalpur, Chennai, Jaipur, Hyderabad, Indore, Patna, Agra, West Bangal, Ranchi, Durg, Bilaspur, Raipur, Satpura, Malwa, Kanpur, Dehradun etc.