When a structure fails, people blame design.

When a machine breaks down, they blame the system.

But ask any experienced engineer or fabricator the truth, and they’ll tell you:

Failures often start at the fasteners.

That tiny bolt, nut, or screw holding everything together? It carries load, resists vibration, faces moisture, chemicals, heat, and time. Choosing the wrong one is expensive. Choosing the right stainless steel fasteners is insurance.

This guide is built from practical industry understanding — not theory — to help you choose, use, and trust the right fasteners for real-world conditions.

What Are Stainless Steel Fasteners and Why Do They Matter?

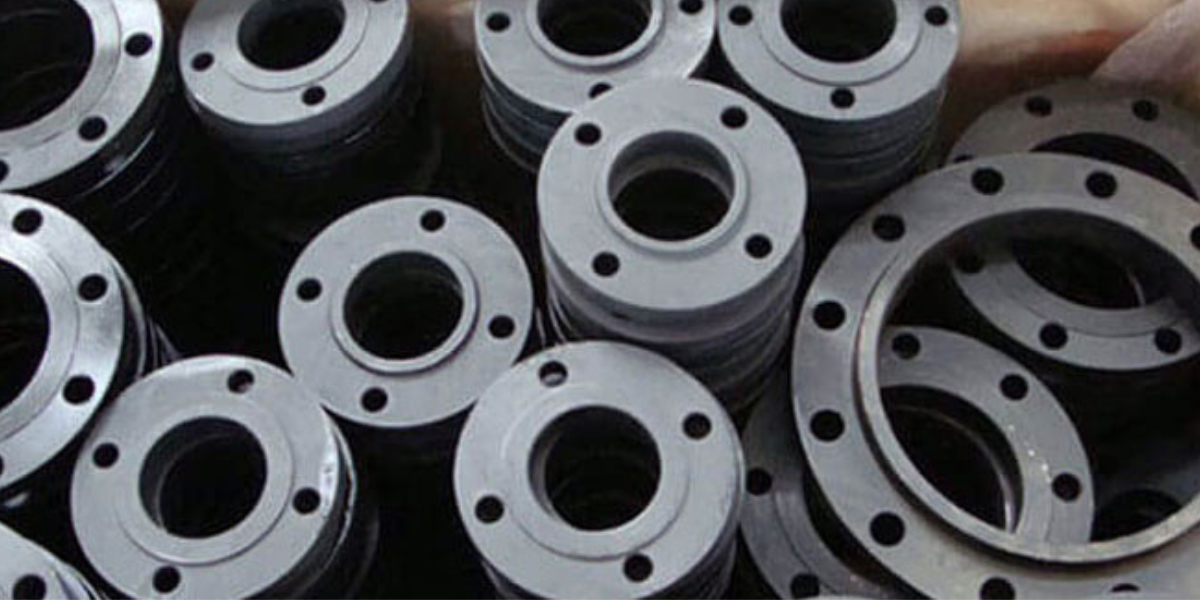

Stainless steel fasteners include bolts, nuts, screws, studs, washers, and anchors made from corrosion-resistant steel alloys. Their job sounds simple: hold components together. Their responsibility is anything but.

They must resist:

- Rust

- Chemical exposure

- Temperature changes

- Mechanical stress

- Vibration and fatigue

That’s why industrial stainless steel fasteners are used in everything from offshore rigs to food processing plants.

A fastener doesn’t just connect parts — it protects your entire system.

Advantages of Stainless Steel Fasteners

Why do professionals consistently choose stainless steel over coated or carbon steel options?

Key Advantages of Stainless Steel Fasteners

The advantages of stainless steel fasteners go far beyond rust resistance:

Corrosion Resistance

These are true corrosion resistant fasteners, ideal for wet, humid, or chemically exposed environments.

Strength and Durability

They maintain structural integrity even under mechanical stress.

Low Maintenance

No frequent repainting or coating repairs needed.

Temperature Resistance

They perform well in both high and low temperatures.

Hygienic Properties

Essential in food, pharma, and medical industries.

Long-Term Cost Savings

Cheaper fasteners may save money today. Stainless saves money over decades.

Bottom line: You install once — and forget about failure.

Types of Stainless Steel Fasteners: Screws, Bolts, Nuts and More

Stainless Steel Screws Bolts Nuts – The Core Categories

In practice, most projects rely on these primary stainless steel screws bolts nuts:

1. Stainless Steel Bolts

Used for structural and heavy-duty connections. Available in hex bolts, carriage bolts, and anchor bolts.

2. Stainless Steel Nuts

Paired with bolts for clamping force. Types include hex nuts, lock nuts, and flange nuts.

3. Stainless Steel Screws

Used in lighter applications, sheet metal, wood, and equipment assembly.

4. Washers and Studs

Distribute load and ensure alignment.

In industrial setups, fastener selection is rarely about size alone — grade and environment matter more.

SS 304 Fasteners – The Industry Workhorse

If stainless steel had a “default setting,” it would be SS 304 fasteners.

What Makes SS 304 Fasteners Popular?

- Excellent corrosion resistance in normal atmospheric conditions

- Good strength and toughness

- Easy fabrication and installation

- Cost-effective compared to higher grades

SS 304 fasteners are commonly used in:

- Construction

- Automotive components

- Food processing equipment

- Interior architectural applications

But here’s the expert truth:

SS 304 fasteners are great — until chlorides enter the picture.

In coastal or chemical-heavy environments, 304 may pit over time. That’s when you move to the next level.

SS 316 Fasteners – Built for Harsh Environments

When exposure gets aggressive, professionals turn to SS 316 fasteners.

Why SS 316 Fasteners Are Superior in Corrosive Conditions

SS 316 contains molybdenum, which boosts resistance against:

- Saltwater

- Chlorides

- Chemical processing environments

- Industrial pollutants

That’s why SS 316 fasteners are widely used as marine grade fasteners.

Applications of SS 316 Fasteners

- Offshore platforms

- Shipbuilding

- Coastal infrastructure

- Chemical plants

- Pharmaceutical equipment

If your fasteners face salt or chemicals daily, SS 316 isn’t an upgrade — it’s a requirement.

Marine Grade Fasteners – Why Regular Fasteners Fail at Sea

Saltwater is brutal. It penetrates coatings, attacks carbon steel, and accelerates corrosion.

Marine grade fasteners — typically SS 316 fasteners — are designed to survive this environment.

Features of Marine Grade Fasteners

- High resistance to salt spray

- Protection against crevice corrosion

- Long-term durability in humid air

This is why docks, boats, offshore rigs, and coastal structures rely heavily on stainless steel fasteners of 316 grade.

Using anything else? That’s a maintenance nightmare waiting to happen.

Industrial Stainless Steel Fasteners in Heavy Applications

Not all environments are wet. Some are hot, vibrating, or chemically active.

Why Industrial Stainless Steel Fasteners Are Critical

Industrial stainless steel fasteners are used in:

- Oil & gas plants

- Power generation

- Chemical processing

- Heavy machinery

- Pressure systems

These settings demand:

- Mechanical strength

- Heat resistance

- Chemical stability

Fastener failure here doesn’t just cause downtime — it can cause safety hazards.

In industrial environments, fasteners are safety components. Not accessories.

Corrosion Resistant Fasteners vs Coated Fasteners

A common mistake? Choosing coated carbon steel instead of true corrosion resistant fasteners.

| Feature | Coated Fasteners | Stainless Steel Fasteners |

| Rust Protection | Surface-level | Built into material |

| Lifespan | Coating wears off | Long-term resistance |

| Maintenance | High | Low |

| Harsh Environments | Poor | Excellent |

Once a coating scratches, corrosion begins. With stainless steel fasteners, protection is part of the alloy.

How to Choose the Right Stainless Steel Fasteners

Ask these expert-level questions:

1. What Environment Will They Face?

- Indoor → SS 304 fasteners

- Coastal/Chemical → SS 316 fasteners

2. Load Requirements?

Heavy loads need higher strength bolts and proper grades.

3. Temperature Exposure?

High heat demands heat-resistant stainless alloys.

4. Is Hygiene Important?

Food and pharma industries prefer stainless steel screws bolts nuts due to cleanability.

5. Risk of Corrosion?

If the answer is “maybe,” choose corrosion resistant fasteners.

Installation Tips from Field Experience

Even the best stainless steel fasteners can fail if installed incorrectly.

Use anti-seize compounds to prevent galling

Apply correct torque values

Avoid mixing dissimilar metals

Ensure threads are clean and aligned

Fastener quality + correct installation = long-term reliability.

Common Myths About Stainless Steel Fasteners

Myth 1: Stainless never rusts

Reality: Poor grade selection can still corrode.

Myth 2: All stainless grades are the same

Reality: SS 304 fasteners and SS 316 fasteners behave very differently.

Myth 3: They’re too expensive

Reality: Failure and maintenance cost more.

Final Thoughts: Why Stainless Steel Fasteners Are a Smart Investment

A fastener is small — but its role is massive.

Choosing stainless steel fasteners means:

- Reliability

- Safety

- Lower maintenance

- Longer equipment life

From marine grade fasteners on offshore rigs to industrial stainless steel fasteners in plants, the message is clear:

If corrosion, safety, and longevity matter — stainless steel isn’t optional. It’s essential.

Because in the real world, systems don’t fail from the middle.

They fail at the connections.

Frequently Asked Questions (FAQs) About Stainless Steel Fasteners

1. What are stainless steel fasteners used for?

Stainless steel fasteners are used to join components in environments where strength, durability, and corrosion resistance are critical. They are widely used in construction, marine, chemical processing, food manufacturing, automotive, and heavy industries. Because they are naturally corrosion resistant fasteners, they are ideal for outdoor, humid, and chemically exposed conditions where regular fasteners would rust or weaken over time.

2. What is the difference between SS 304 fasteners and SS 316 fasteners?

The main difference between SS 304 fasteners and SS 316 fasteners is corrosion resistance. SS 316 contains molybdenum, which improves resistance to chlorides, saltwater, and chemicals. SS 304 fasteners are suitable for general indoor and mild outdoor environments, while SS 316 fasteners are preferred in marine, coastal, and chemical industries where corrosion risk is high.

3. Why are stainless steel fasteners considered corrosion resistant fasteners?

Stainless steel fasteners contain chromium, which forms a protective oxide layer on the surface. This layer prevents rust and corrosion from penetrating the metal. Unlike coated fasteners, the corrosion resistance is built into the material itself, making them true corrosion resistant fasteners suitable for long-term use in aggressive environments.

4. What types of stainless steel screws, bolts, and nuts are commonly used?

The most common stainless steel screws bolts nuts include hex bolts, carriage bolts, machine screws, self-tapping screws, hex nuts, lock nuts, and washers. These fasteners are used across structural, mechanical, and assembly applications where strength and corrosion resistance are required.

5. Are SS 316 fasteners really necessary for marine environments?

Yes. SS 316 fasteners are widely known as marine grade fasteners because they offer superior resistance to saltwater corrosion. Standard grades like SS 304 may develop pitting and corrosion over time in salty environments, whereas SS 316 performs reliably in boats, docks, offshore platforms, and coastal structures.

6. What are the advantages of stainless steel fasteners over coated fasteners?

The advantages of stainless steel fasteners include long-term corrosion resistance, low maintenance, high strength, temperature resistance, and better durability. Coated fasteners may rust once the coating wears off, but stainless steel fasteners provide protection throughout the material, making them more reliable and cost-effective over time.

7. Where are industrial stainless steel fasteners commonly used?

Industrial stainless steel fasteners are used in oil and gas plants, power generation facilities, chemical industries, food processing units, pharmaceutical manufacturing, and heavy machinery. These environments demand high strength and resistance to corrosion, heat, and chemicals.

8. Do stainless steel fasteners require special installation methods?

Yes, proper installation is important. Stainless steel fasteners are prone to galling (thread seizing), so using anti-seize lubricants and correct torque values is recommended. Proper alignment and avoiding mixing with dissimilar metals also help ensure long service life.

9. Are SS 304 fasteners suitable for outdoor applications?

SS 304 fasteners can be used outdoors in mild environments, but they may not perform well in coastal or highly polluted industrial areas. In such cases, SS 316 fasteners are a better option due to higher resistance to salt and chemicals.

10. Why are stainless steel fasteners a long-term cost-saving solution?

Although stainless steel fasteners may have a higher initial cost, they reduce maintenance, replacement frequency, and failure risks. Their durability, strength, and corrosion resistance make them a smart long-term investment compared to cheaper alternatives that fail sooner.