Alloy Steel Flanges Manufacturers and Exporters

Alloy Steel Sheets Plates and Coils, ASTM A387 Alloy Sheet, Alloy Steel Plates, Alloy Steel Circle, Alloy Steel Coils, ASME SA 387 Alloy Steel Plates, Alloy Steel Hot Rolled Plates Supplier in Mumbai, India.

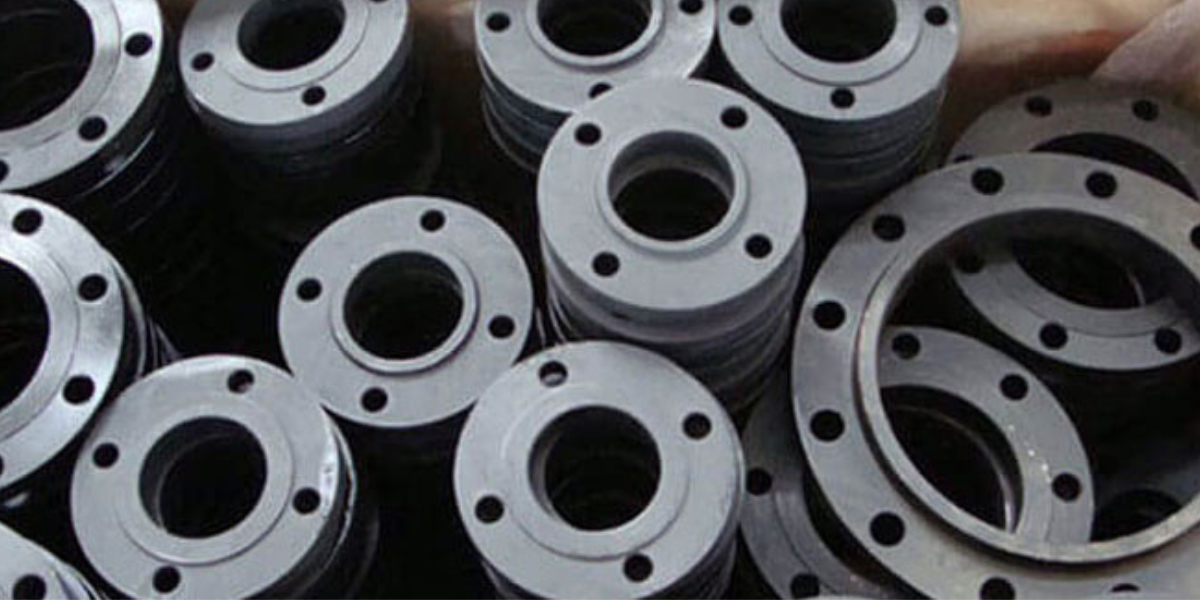

Alloy Steel Flanges are made up of different alloys that have different material compositions. Their mechanical properties vary with the composition and the dimensions vary with the standards. There are different types of alloys that belong to ASME A182 grades. The grades can range as F5, F9, F11 and so on. The Alloy Steel Blind Flanges are closed ended flanges that end a pipeline. There are different types of blind flanges and shapes for different types of applications. There are also other types such as socket weld flanges, weld neck flanges, SWRF flanges and Alloy Steel Slip On Flange types. The slip on flanges are one of the most used types for the ease of application and the accuracy in connection point. The flanges range in sizes from ½ inches to 48 inches. The AS Pipe Flange dimensions are specified by the ANSI, ASME, ASTM, DIN and all other international standards. Depending on the need for mechanical properties, the high alloy or low alloy flanges can be used. The Low Alloy Steel Flange has low amounts of alloying elements where the high alloy flanges have higher amounts of alloying elements; sometimes, commercially pure elements as well. The different production types such as the Alloy Steel Threaded Flange, plate flange, screwed flange and the forged flanges are used in different types of applications. The applications include oil and gas, petroleum, water lines, high temperature services, low temperature services, chemical plants, food production plants, acid processing plants and other industrial applications.

Features of Alloy Steel Flanges :-

| High strength | Resistance against corrosion |

| Resistance against High pressure | Resistance against High temperature |

| Resistance against Dimensions stability | Longer service life |

| Resistance against High mechanical stress | |

Alloy Steel Flanges Specifications :

Specifications |

ASTM A182 / ASME SA182 |

|---|---|

| ASME B16.5 size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Standards | BS4504, BS 10, EN-1092, DIN, ANSI, ASME, ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS, DIN, EN, GOST. |

| Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

Alloy Steel Flanges: Precision-Engineered Connection Solutions for Critical Piping Systems

In the intricate world of industrial piping infrastructure, alloy steel flanges serve as the cornerstone of secure, leak-free connections that withstand extreme operational demands. These essential components enable the assembly, maintenance, and modification of complex piping networks while maintaining system integrity under challenging conditions. Arham Alloys has earned recognition as premier alloy steel flanges manufacturers in India, delivering products that combine metallurgical excellence with precision engineering to meet the exacting requirements of diverse industrial applications worldwide.

Metallurgical Foundations: Understanding Alloy Composition and Performance

Alloy steel flanges derive their exceptional properties from carefully balanced chemical compositions where strategic alloying elements transform basic steel into high-performance materials. The incorporation of chromium, molybdenum, nickel, vanadium, and other elements creates components capable of withstanding corrosive environments, elevated temperatures, and extreme pressures that would rapidly degrade ordinary carbon steel flanges.

The ASME A182 specification encompasses numerous grades of alloy steel flanges, each formulated for specific service conditions and performance requirements. Grade F5 contains chromium and molybdenum for enhanced strength and moderate corrosion resistance, making it suitable for refinery service and hydrocarbon processing. Grade F9 provides improved high-temperature strength for applications in power generation and chemical processing. Grade F11 offers excellent creep resistance for sustained elevated-temperature service, while higher grades deliver progressively enhanced capabilities for increasingly demanding applications.

Comprehensive Range: Exploring Flange Types and Configurations

The versatility of alloy steel flanges manifests in the diverse configurations available to accommodate varying piping system requirements. Blind flanges provide sealed terminations for pipeline ends or unused branch connections, effectively capping pressurized systems while allowing future access if operational needs change. The robust construction of alloy steel blind flanges ensures reliable sealing even under full system pressure, preventing potentially hazardous leaks at terminal points.

Weld neck flanges represent the premium choice for high-pressure or high-temperature applications where structural integrity cannot be compromised. The gradual transition from pipe wall to flange thickness through the integral neck minimizes stress concentration, distributing loads smoothly and preventing fatigue failures at critical connection points. This superior design makes weld neck alloy steel flanges indispensable in petrochemical processing, power generation, and other demanding services where failure consequences would be catastrophic.

Slip-on flanges offer practical advantages in ease of installation and alignment accuracy, making them among the most widely specified alloy steel flanges for general industrial applications. The simple design allows the pipe to slip inside the flange bore before welding, facilitating proper alignment and reducing installation time compared to weld neck configurations. While not rated for the most extreme service conditions, slip-on flanges provide excellent performance across a broad range of moderate-pressure applications at reasonable cost.

Manufacturing Excellence: From Raw Material to Finished Product

Our reputation as leading alloy steel flanges manufacturers in India stems from rigorous manufacturing processes that ensure dimensional accuracy, metallurgical integrity, and consistent quality. Production begins with premium-grade steel sourced from certified mills with proven quality control systems. These raw materials undergo thorough incoming inspection including chemical composition verification, mechanical property testing, and dimensional checks before release to production.

Forging operations shape alloy steel flanges while refining grain structure and enhancing mechanical properties through controlled deformation. The hot forging process breaks up casting structures from ingot production, creating uniform grain flow that follows flange contours and improves strength in critical stress directions. Precision machining operations following forging ensure that bolt hole locations, facing dimensions, and sealing surfaces meet exacting tolerances specified by international standards.

Heat treatment processes tailor the final properties of alloy steel flanges to application requirements. Normalizing refines grain structure and relieves residual stresses from forging and machining operations. Tempering following quenching operations adjusts the hardness-toughness balance, optimizing properties for specific service conditions. Our metallurgical expertise ensures appropriate heat treatment for each alloy grade and flange configuration, maximizing performance and service life.

Dimensional Standards and International Specification Compliance

Alloy steel flanges manufactured in our facilities conform to comprehensive dimensional standards including ANSI, ASME, ASTM, DIN, and other international specifications that govern flange design and dimensions. These standards establish critical parameters including pressure-temperature ratings, flange facing configurations, bolt hole patterns, and gasket seating surfaces. Adherence to these specifications ensures interchangeability and compatibility with piping components from various manufacturers worldwide.

Size availability spans from compact half-inch diameter flanges for instrument connections to massive 48-inch diameter flanges for large-diameter process piping and transfer lines. This comprehensive size range enables alloy steel flanges to address virtually any piping application regardless of scale. Standard pressure classes ranging from 150 to 2500 accommodate service conditions from low-pressure utility systems to ultra-high-pressure process applications in chemical synthesis and specialty manufacturing.

Low Alloy vs. High Alloy: Strategic Material Selection for Optimal Performance

Low alloy alloy steel flanges contain modest quantities of alloying elements—typically less than eight percent total—providing enhanced properties compared to carbon steel while maintaining cost-effectiveness. These materials offer substantial improvements in strength, toughness, and corrosion resistance sufficient for many industrial applications without the premium investment required for high alloy grades. The balanced performance-cost equation makes low alloy flanges ideal for applications where extreme conditions do not justify high alloy specifications.

High alloy alloy steel flanges incorporate elevated levels of alloying elements, often exceeding ten percent chromium plus additional molybdenum, nickel, and other strategic additions. Some specialized grades approach commercially pure alloying element concentrations in specific components of their composition. This intensive alloying delivers dramatically enhanced corrosion resistance, high-temperature strength retention, and specialized properties like oxidation resistance or sulfidation resistance. While commanding premium prices, high alloy flanges prove economical in severe service applications where frequent replacement of inferior materials would generate excessive downtime costs.

Specialized Configurations: Threaded, Socket Weld, and Custom Designs

Threaded alloy steel flanges provide convenient connections for smaller diameter piping where welding may be impractical or where future disassembly is anticipated. The internal threads machined into these flanges engage with externally threaded pipe or nipples, creating secure mechanical connections suitable for moderate-pressure applications. The superior strength of alloy materials enables threaded flanges to achieve pressure ratings comparable to welded configurations in similar sizes, expanding application possibilities.

Socket weld flanges combine ease of installation with the structural integrity of welded connections. The pipe inserts into a recessed socket machined into the flange bore, where a fillet weld around the pipe exterior creates a permanent, leak-tight joint. This configuration simplifies alignment while providing full penetration welds that develop the complete strength of adjacent components. Socket weld alloy steel flanges prove particularly valuable in high-vibration applications where threaded connections might loosen over time.

Plate flanges machined from heavy plate stock offer economical solutions for large-diameter, low-pressure applications where forged flanges would be cost-prohibitive. While not suitable for the most demanding service conditions, plate alloy steel flanges provide reliable performance in utility piping, ventilation systems, and other applications where moderate pressure ratings suffice. Screwed flanges accommodate special connection requirements in systems using non-standard pipe threads or proprietary coupling designs.

Industrial Applications: Serving Diverse Sectors with Specialized Solutions

Oil and gas production operations demand alloy steel flanges capable of withstanding sour service conditions, high pressures, and the corrosive effects of hydrogen sulfide and carbon dioxide. Wellhead flanges must maintain leak-tight sealing despite thermal cycling, vibration, and the erosive effects of produced fluids carrying formation sand and corrosion products. The combination of high strength and corrosion resistance makes alloy steel the material of choice for these critical applications where failure could result in environmental disasters.

Petrochemical processing facilities utilize alloy steel flanges throughout complex piping networks handling aggressive chemicals at elevated temperatures and pressures. Catalytic cracker units, hydroprocessing systems, and aromatics production plants subject flanges to severe conditions that rapidly degrade inferior materials. The dimensional stability of properly selected alloy flanges prevents leaks caused by thermal expansion mismatches, while corrosion resistance maintains sealing surface integrity throughout extended operational campaigns.

Chemical manufacturing plants rely on alloy steel flanges for handling acids, bases, oxidizers, and specialty chemicals that attack ordinary materials. The passive chromium oxide layer on high-chromium alloy flanges provides reliable corrosion protection across broad pH ranges and oxidizing potential levels. Process flexibility enabled by flanged connections allows rapid reconfiguration of production equipment to accommodate changing product slates and manufacturing campaigns.

High-Temperature Service: Maintaining Integrity Under Thermal Stress

Power generation facilities operate steam systems at temperatures and pressures where material selection becomes critical to long-term reliability. Alloy steel flanges in superheated steam service must resist creep deformation—the gradual plastic deformation that occurs under sustained loading at elevated temperatures. Alloying elements like molybdenum and vanadium create stable carbide precipitates that pin grain boundaries and dislocations, dramatically improving creep resistance compared to carbon steel.

Thermal cycling represents another challenge in high-temperature applications where equipment experiences repeated startup and shutdown cycles. The thermal fatigue resistance of properly designed alloy steel flanges prevents crack initiation and propagation that would compromise joint integrity. The controlled thermal expansion characteristics match adjacent piping materials, minimizing differential movement that generates excessive stress at bolted connections.

Oxidation resistance becomes paramount in high-temperature gas service where exposed metal surfaces react with atmospheric oxygen. The protective oxide scales formed on high-chromium alloy steel flanges remain adherent and slow-growing even at elevated temperatures, preventing the accelerated metal loss that occurs when non-protective oxide scales spall repeatedly. This stability maintains flange dimensions and sealing surface flatness throughout years of high-temperature exposure.

Cryogenic Applications: Performance in Extreme Cold

Low-temperature services present unique challenges where ordinary materials become brittle and susceptible to catastrophic failure. Specially formulated alloy steel flanges maintain toughness and ductility at cryogenic temperatures encountered in liquefied natural gas terminals, air separation plants, and industrial gas production facilities. Nickel additions prove particularly effective at preserving low-temperature toughness, preventing the ductile-to-brittle transition that renders some materials dangerously fragile in extreme cold.

The dimensional stability of alloy steel flanges through temperature cycling from ambient to cryogenic conditions prevents loosening of bolted connections that could lead to leaks. Thermal contraction coefficients matching adjacent piping components ensure that flanged joints maintain proper gasket compression throughout cool-down and warm-up cycles. This reliability proves essential in applications handling hazardous or expensive cryogenic fluids where even minor leaks generate significant consequences.

Quality Assurance: Rigorous Testing and Certification Protocols

Comprehensive quality control measures implemented by alloy steel flanges manufacturers in India ensure that every product meets specified performance standards. Chemical composition analysis using optical emission spectrometry verifies that alloying elements fall within grade specifications. Mechanical property testing includes tensile strength measurement, hardness evaluation, and impact toughness assessment at relevant service temperatures.

Dimensional inspection protocols confirm that alloy steel flanges conform to applicable standards and drawing specifications. Coordinate measuring equipment checks critical dimensions including bolt circle diameter, bolt hole locations, flange facing geometry, and hub dimensions with precision exceeding standard tolerances. Non-destructive examination techniques including ultrasonic testing, magnetic particle inspection, and liquid penetrant examination detect surface and subsurface discontinuities that could compromise performance.

Hydrostatic pressure testing validates structural integrity under simulated service pressures. Each alloy steel flange undergoes pressure testing at levels exceeding rated working pressures, demonstrating adequate strength margins and freedom from through-wall defects. Complete documentation including certified mill test reports, heat numbers, and quality control records accompanies shipments, providing traceability and satisfying customer quality assurance requirements.

Strategic Advantages: Mumbai Manufacturing Hub and Export Capabilities

Our position as prominent alloy steel flanges manufacturers in India offers significant competitive advantages for domestic and international customers. Mumbai’s strategic location provides excellent access to world-class port facilities, enabling efficient export operations with competitive freight rates and reliable transit times to global destinations. The city’s comprehensive industrial infrastructure supports specialized services including advanced heat treatment, precision machining, and sophisticated testing capabilities.

The concentration of technical expertise and skilled workforce in Mumbai’s industrial ecosystem ensures our manufacturing operations maintain the highest standards of quality and efficiency. Access to supporting industries—including raw material suppliers, tooling manufacturers, and logistics providers—creates a seamless supply chain that delivers products on schedule while maintaining cost competitiveness. This integrated infrastructure enables us to offer complete solutions rather than simply commoditized products.

Technical Support and Engineering Collaboration Services

Our commitment as experienced alloy steel flanges manufacturers in India extends beyond product supply to comprehensive technical support throughout project lifecycles. Engineering teams collaborate with customers during design phases, recommending optimal alloy grades and flange configurations that balance performance requirements with budget constraints. Finite element analysis capabilities enable stress evaluation of complex piping geometries, identifying potential issues before fabrication begins.

Installation guidance addresses proper gasket selection, bolt tightening procedures, and alignment techniques that ensure leak-free joints and optimal performance. Our specialists provide welding procedure specifications tailored to specific alloy steel flanges grades, ensuring field installations achieve full structural integrity. Whether your application involves routine maintenance or the construction of new facilities, Arham Alloys delivers the expertise, products, and support that guarantee successful outcomes. Contact our technical team to discover how our alloy steel flanges can enhance your system’s reliability, safety, and operational efficiency.

Product Usage & Application:-

- Useful in Paper & Pulp Companies

- Useful in High-Pressure Applications

- Useful in Oil and Gas Industry

- Useful in Chemical Refinery

- Useful in Pipeline

- Useful in High-Temperature Application

- Useful in Water Pipe Line

- Useful in Nuclear Power Plants

- Useful in Food Processing and Dairy Industries

- Useful in Boiler & Heat Exchangers

FAQs

1. What are alloy steel flanges and why are they widely used in industrial piping?

Alloy steel flanges are forged or machined components used to connect pipes, valves, pumps, and other equipment in piping systems. These flanges are manufactured from alloy steels containing elements like chromium, molybdenum, and nickel, which improve strength, corrosion resistance, and high-temperature performance. Industries such as oil & gas, petrochemical, power generation, and marine rely on alloy steel flanges because they offer excellent durability under extreme pressure and temperature conditions while maintaining structural integrity over long service lives.

2. Why should buyers choose experienced alloy steel flanges manufacturers in India?

Working with established alloy steel flanges manufacturers in India ensures access to cost-effective production, advanced metallurgy expertise, and compliance with international standards such as ASTM, ASME, and ANSI. Indian manufacturers often combine modern infrastructure with skilled engineering, enabling them to deliver high-quality alloy steel flanges in bulk quantities while maintaining competitive pricing and reliable export logistics.

3. What types of alloy steel flanges do manufacturers typically supply?

Leading alloy steel flanges manufacturers in India produce a wide variety of flange types to suit different industrial needs, including:

- Weld Neck Flanges

- Slip-On Flanges

- Blind Flanges

- Socket Weld Flanges

- Threaded Flanges

- Lap Joint Flanges

Each type of alloy steel flanges serves a specific function depending on pressure rating, installation method, and maintenance requirements.

4. How do alloy steel flanges manufacturers ensure product quality?

Reputable alloy steel flanges manufacturers in India follow strict quality assurance systems. At Arham Alloys, for example, production begins with carefully selected raw materials that comply with international composition standards. State-of-the-art manufacturing facilities, controlled processing operations, and rigorous inspection procedures help achieve precise dimensions and required mechanical properties. Testing methods such as chemical analysis, mechanical testing, and dimensional checks ensure every batch of alloy steel flanges meets customer and regulatory expectations.

5. What standards do alloy steel flanges usually conform to?

Most alloy steel flanges are produced in accordance with international specifications such as:

- ASTM A182

- ASME B16.5 / B16.47

- ANSI standards

- DIN and EN standards

Trusted alloy steel flanges manufacturers in India provide material test certificates and documentation to verify compliance, ensuring safe use in critical industrial systems.

6. What industries commonly use alloy steel flanges?

Alloy steel flanges are essential in industries where high strength and resistance to heat and corrosion are required. These include:

- Oil and Gas Processing

- Refineries and Petrochemical Plants

- Power Plants

- Shipbuilding

- Chemical Processing Units

- Water Treatment Facilities

Because of their reliability, alloy steel flanges manufacturers in India export these products worldwide for demanding infrastructure projects.

7. What makes Arham Alloys a reliable supplier of alloy steel flanges?

Arham Alloys utilizes modern production facilities and strict quality control systems to ensure consistent product performance. The company emphasizes precise processing techniques and controlled operations to achieve the required mechanical properties. With expertise in supplying materials in various delivery conditions and dimensions, Arham Alloys supports manufacturers seeking dependable alloy steel flanges that meet exact project specifications while maintaining international quality benchmarks.

8. Can alloy steel flanges be customized as per project requirements?

Yes, most alloy steel flanges manufacturers in India offer customization in terms of size, pressure rating, material grade, and surface finish. Customization ensures compatibility with existing piping systems and operational demands. Buyers can request specific grades, dimensions, and tolerances to suit unique industrial applications.

9. What factors should be considered when selecting alloy steel flanges manufacturers in India?

When choosing among alloy steel flanges manufacturers in India, consider:

- Compliance with global standards

- Manufacturing infrastructure

- Quality certifications and testing capabilities

- Experience in export markets

- Customization options

- Timely delivery and technical support

Selecting the right supplier ensures long-term reliability of alloy steel flanges in critical applications.

10. How do alloy steel flanges support long-term operational efficiency?

High-quality alloy steel flanges reduce the risk of leakage, system failure, and maintenance downtime. Their enhanced strength and corrosion resistance help maintain system performance even under harsh operating environments. By sourcing from reputable alloy steel flanges manufacturers in India, industries benefit from durable components that improve safety, reduce lifecycle costs, and ensure uninterrupted production.

We Export To :

Kazakhstan, Algiers, Johannesburg, Pretoria, Dakar, Ghana, Uganda, Mozambique, Iraq, Subra al-Haymah, Australia, Yaoundé, South Africa, Saudi Arabia, Kampala, Benin, Ethiopa, Kuwait, Luanda, Abu Dhabi, Peru, Sudan, Colombia, Nairobi, Turkey, Russia, Khartoum, Kano, UAE, Bahrain, Cape Town, Trinidad and Tobago, Dar es Salaam, Nigeria, Antananarivo, Tripoli, Addis Ababa, London, Douala, Lebanon, Tunisia, Ouagadougou, Mogadishu, Harare, Mbuji-Mayi, Qatar, Zaria, Soweto, Omdurman, Angola, Alexandria, Dubai, Yemen, Casablanca, Africa, Oman, Giza, Kinshasa, Bamako, UK, Houston, Accra, Algeria, Argentina, Cairo, Chine, Kolwezi, Hong Kong, Abidjan, Vietnam, Port Elizabeth, Maputo, Maiduguri, Canada, Port Harcourt, Singapore, Egypt, Venezuela, Freetown, Ibadan, Iran, Fez, Malaysia, Mexico, Cameroon, New York, Indonesia, Italy, Azerbaijan, Israel, Conakry, Brazil, Democratic Republic of the Congo, New Zealand, Morocco, Jordan, United States, Thailand (Bangkok), Cyprus, Sri Lanka, Rabat, Bulawayo, Kaduna, Durban, Colombo, Germany, Lubumbashi, Lagos, Brazzaville.

We Supply To :

Tripura, Ahmedabad, Kolkata, Lucknow, Andhra Pradesh, Pune, Ambala, Maiduguri, Buxar, Puducherry, Karnataka, Maharashtra, Bhiwadi, Surat, Mizoram, Manipur, Delhi, Bangalore, Kerala, Ballia, Jamalpur, Chennai, Jaipur, Hyderabad, Indore, Patna, Agra, West Bangal, Ranchi, Durg, Bilaspur, Raipur, Satpura, Malwa, Kanpur, Dehradun etc.