Aluminium Flanges Manufacturers and Exporters.

Aluminium Flanges, Aluminium 6061 Plate Flanges, Aluminium Alloy 6063 Industrial Flanges Manufacturers in India, Aluminium Alloy 6082 Pipe Flanges, Aluminium 5083 Flanges, High Quality Aluminium Flanges Supplier in Mumbai, India.

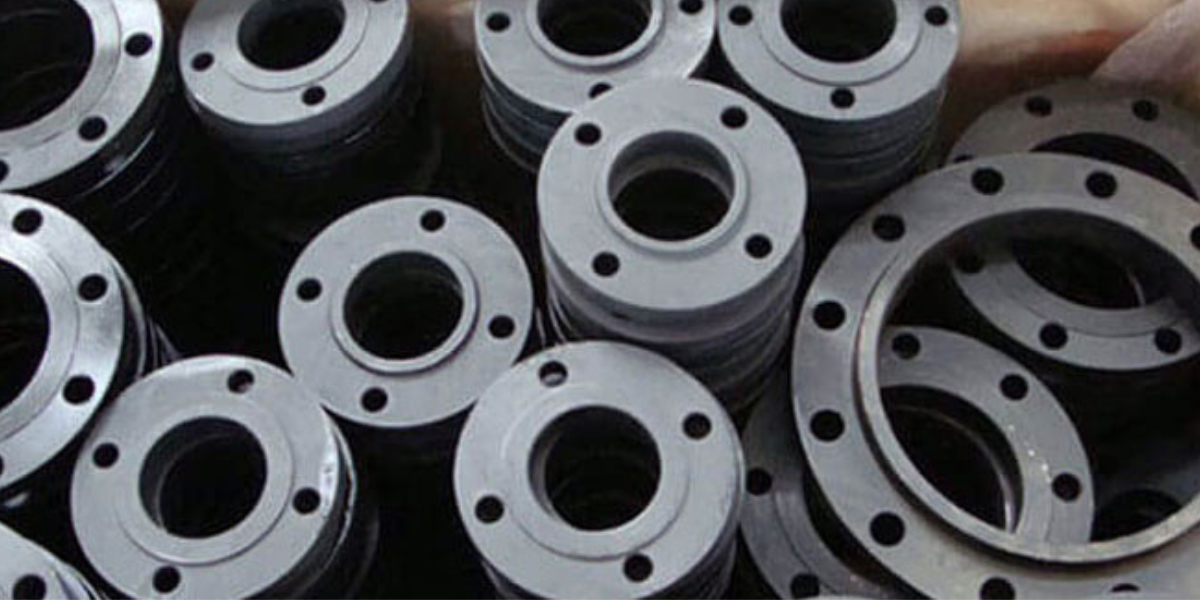

Aluminium Flanges that is meant to easily cater to various industrial applications in different domains. The applications of these flanges can be traced to various industrial domains that are highly convenient for our customers and clients. The raw material used for manufacturing and fabricating these flanges is known to be purchased from the experienced distributors at fairly rates. Our team of experts studies and analyzes the behavioral patterns and quality of raw material. The technological superiority of the manufactured product enable is to provide our clients and customers with flawless and prompt services

The tests include pitting resistance test, flaring test, flattening test, third-party inspection, durability test, positive material identification test, ultrasonic test, and destructive test. When all the tests are done and flanges are ready for the delivery, they are packed in the high quality of packaging material like wooden cases/ pallets/ carton boxes which in turn help prevent damages and avoid rust until Aluminium Alloy Flanges reaches its respective destinations.

Features of Aluminium Flanges :-

| High strength | Resistance against corrosion |

| Resistance against High pressure | Resistance against High temperature |

| Resistance against Dimensions stability | Longer service life |

| Resistance against High mechanical stress | |

Aluminium Alloy 6061 Flanges Specification

Aluminium Alloy :ASTM / ASME

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Aluminium Flanges Chemical Composition :

| Grade | Si | Fe | Cu | Zn | Mn | Mg | Ti | Cr | Al | Others(Total) |

| Aluminium | 0.40 – 0.80 | 0.70 max | 0.15-0.40 | 0.25 max | 0.15 | 0.8-1.2 | 0.15 max | 0.04-0.35 | Balance | 0.15 max |

Mechanical Properties for Aluminium Flanges :

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T6, T651 | 45 | 310 | 21 | 145 | 25 | 65 |

Physical Property for Aluminium Flanges :

| Physical Property | Value |

| Density | 2,70 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 x 10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | %43 IACS |

Arham Alloys: Premier Aluminium Flanges Manufacturers and Exporters in Mumbai

In the intricate world of piping systems and pressure vessel construction, the quality and material selection of connection components fundamentally determine the efficiency, reliability, and operational lifespan of industrial facilities. Arham Alloys has established itself as a leading manufacturer and exporter of high-quality aluminium flanges throughout India and international markets. Based in Mumbai, our commitment to manufacturing excellence and comprehensive product offerings has made us the trusted supplier for industries requiring lightweight, corrosion-resistant aluminium flanges that deliver exceptional performance across diverse applications.

Understanding Aluminium Flanges: Lightweight Solutions for Critical Connections

Aluminium flanges serve as essential mechanical components that provide a method for connecting pipes, valves, pumps, and other equipment to form complete piping systems. These circular discs with precisely machined bolt holes enable the assembly of piping networks that can be inspected, maintained, and modified when necessary, all while offering significant weight advantages over traditional steel flanges. The aluminium pipe flange connection system combines the flexibility required for maintenance operations with the structural integrity demanded by pressurized systems, making material selection critical for long-term performance.

The fundamental distinction of aluminium flanges lies in their exceptional weight-to-strength ratio and superior corrosion resistance. With approximately one-third the density of steel, aluminium flanges dramatically reduce installation weight, minimizing structural support requirements and simplifying handling during construction and maintenance operations. This weight reduction becomes particularly valuable in applications involving elevated piping, offshore installations, or situations where manual handling is necessary during installation or service activities.

Comprehensive Range of Aluminium Alloy Grades

At Arham Alloys, we manufacture aluminium flanges in various alloy grades to address the complete spectrum of performance requirements across different industrial applications. Our product portfolio encompasses grades optimized for specific combinations of strength, corrosion resistance, formability, and weldability. This comprehensive grade selection ensures that customers can specify the optimal material for their specific service conditions and operational demands.

Aluminium 6061 Plate Flanges for Versatile Applications

Our aluminium 6061 plate aluminium flanges represent one of the most widely used grades, offering an excellent balance of mechanical properties, corrosion resistance, and machinability. This heat-treatable alloy delivers good strength characteristics suitable for moderate-pressure applications combined with the weldability required for fabricated piping systems. The T6 temper condition provides optimized mechanical properties through precipitation hardening, making 6061 the preferred choice for general industrial applications where reliability and versatility are essential.

The formability and machinability of 6061 aluminium flanges facilitate efficient manufacturing and field modifications when necessary. This grade serves reliably across applications from chemical processing to water treatment facilities, demonstrating consistent performance in diverse service environments.

Aluminium Alloy 6063 Industrial Flanges for Architectural Applications

Aluminium alloy 6063 industrial aluminium flanges offer excellent extrudability and superior surface finish characteristics, making them particularly valuable in architectural and decorative applications. While providing moderate strength, this grade excels in corrosion resistance and aesthetic appeal. The fine grain structure achievable with 6063 enables production of flanges with attractive appearance suitable for visible installations in commercial buildings, water features, and architectural piping systems.

Aluminium Alloy 6082 Pipe Flanges for Enhanced Strength

When applications demand higher strength while maintaining good corrosion resistance and formability, our aluminium alloy 6082 pipe aluminium flanges provide superior performance. This medium-strength alloy offers approximately 20% greater strength than 6061 while retaining excellent welding characteristics. Transportation industries, structural piping applications, and installations requiring enhanced mechanical properties particularly value 6082 flanges for their combination of strength and lightweight characteristics.

Aluminium 5083 Flanges for Marine and Corrosive Environments

For environments involving saltwater exposure, highly corrosive atmospheres, or aggressive chemical service, our aluminium 5083 aluminium flanges deliver exceptional corrosion resistance. This non-heat-treatable alloy maintains its properties in welded assemblies without post-weld heat treatment requirements, critical for fabricated systems. Marine industries, offshore installations, coastal facilities, and chemical processing plants extensively specify 5083 grade for its superior performance in the most challenging corrosive environments.

The excellent weldability and crack resistance of 5083 aluminium flanges make them ideal for complex piping assemblies requiring multiple flanged connections. From shipboard systems to offshore platform installations, these flanges provide decades of reliable service where steel alternatives would experience rapid degradation.

Key Aluminium Flange Advantages in Modern Industry

The selection of aluminium flanges over traditional materials provides numerous aluminium flange advantages that extend beyond initial cost considerations. The dramatic weight reduction achieved with aluminium flanges translates into lower structural support costs, reduced foundation requirements, and simplified installation logistics. This weight advantage becomes particularly significant in retrofit applications where existing structures may have limited load-bearing capacity or in mobile equipment where every kilogram affects performance.

The superior corrosion resistance of aluminium flanges represents another critical advantage, with the natural oxide layer providing self-healing protection against atmospheric moisture, many chemicals, and marine environments. This eliminates the need for protective coatings, periodic painting, or cathodic protection systems required by steel flanges. The aluminium flange advantages in maintenance reduction alone often justify material selection, as aluminium flanges maintain their integrity and appearance throughout decades of service with minimal intervention.

Non-magnetic properties provide additional aluminium flange advantages in applications near sensitive electronic equipment, medical imaging systems, or scientific instrumentation where magnetic interference must be eliminated. The excellent thermal conductivity of aluminium facilitates heat dissipation in systems experiencing temperature variations, while low-temperature toughness prevents brittle fracture in cryogenic services. The electrical conductivity of aluminium flanges can be beneficial or detrimental depending on application requirements, making proper grounding and isolation critical in electrical systems.

Diverse Aluminium Flange Uses Across Industries

The versatility of aluminium flanges enables aluminium flange uses across virtually every industrial sector. Chemical processing facilities employ these flanges throughout their operations for handling various chemicals where material compatibility and corrosion resistance are essential. The aluminium pipe flange connections in chemical plants must withstand exposure to acids, bases, solvents, and reactive compounds while maintaining seal integrity and mechanical strength. The corrosion resistance to many process chemicals makes aluminium suitable for piping systems, storage tank connections, and process equipment assemblies.

Water and Wastewater Treatment Applications

Water treatment facilities represent major aluminium flange uses where corrosion resistance and weight advantages prove particularly valuable. Municipal water systems, desalination plants, and wastewater treatment facilities extensively employ aluminium flanges for piping networks, pumping systems, and treatment equipment. The resistance to chlorinated water, variable pH conditions, and biological activity ensures reliable long-term performance. The lightweight nature of aluminium simplifies maintenance operations and reduces worker fatigue during valve servicing and equipment replacement.

Marine and Offshore Installations

Marine environments present extreme challenges for piping components due to saltwater exposure, humidity, and atmospheric salt contamination. Aluminium flange uses in shipboard installations, dock facilities, and offshore platforms capitalize on the exceptional corrosion resistance of aluminum alloys. From freshwater distribution systems to seawater cooling circuits, aluminium flanges deliver reliable performance where steel alternatives would require frequent inspection and replacement.

Food and Beverage Processing

Food processing and beverage production facilities specify aluminium flanges for sanitary piping systems requiring smooth surfaces, corrosion resistance to cleaning chemicals, and material purity. The aluminium flange uses in these industries include process piping for liquids, slurries, and pneumatic conveyance systems. The non-contaminating nature of aluminum combined with its cleanability enables compliance with strict food safety regulations and quality standards.

HVAC and Refrigeration Systems

Heating, ventilation, air conditioning, and refrigeration systems employ aluminium pipe flange connections throughout their installations. The excellent thermal conductivity enhances system efficiency while the corrosion resistance ensures reliable performance in condensing environments. The aluminium flange uses in HVAC range from chilled water distribution to refrigerant piping to air handling equipment.

Architectural and Building Services

Modern architecture increasingly incorporates exposed piping and building services as design elements. The attractive appearance and weather resistance of aluminium flanges make them ideal for visible installations in commercial buildings, public spaces, and architectural water features. The low maintenance requirements and durability of aluminium flange uses in architectural applications ensure that installations maintain their aesthetic appeal throughout building life.

Superior Manufacturing Process and Quality Control

At Arham Alloys, the raw material used for manufacturing and fabricating these aluminium flanges is purchased from experienced distributors at fair rates. Our procurement process emphasizes material quality and consistency, recognizing that superior finished products begin with premium raw materials. Our team of experts studies and analyzes the behavioral patterns and quality of raw material before approval for production use, ensuring that only materials meeting our stringent standards enter the manufacturing process.

The technological superiority of our manufactured aluminium flanges enables us to provide clients and customers with flawless and prompt services. Advanced machining equipment produces the tight dimensional tolerances required for proper gasket sealing and bolt alignment. Precision boring operations create accurate internal diameters matching pipe specifications, while facing operations produce the smooth gasket seating surfaces essential for leak-tight connections. Our manufacturing capabilities accommodate custom flange designs and non-standard dimensions when standard products cannot satisfy specific application requirements.

Comprehensive Testing and Quality Assurance

Quality verification represents a critical aspect of our aluminium flanges manufacturing process. The tests include pitting resistance testing to evaluate corrosion susceptibility, flaring tests to verify formability characteristics, and flattening tests to confirm material ductility. Third-party inspection services provide independent verification of dimensional accuracy and material properties for critical applications requiring enhanced documentation.

Durability testing subjects aluminium flanges to simulated service conditions including pressure cycles, temperature variations, and environmental exposure to predict field performance. Positive material identification testing confirms alloy composition using non-destructive spectroscopic analysis, ensuring that each batch contains the specified grade. Ultrasonic testing detects any internal defects or discontinuities that could compromise performance, while destructive testing on representative samples verifies mechanical properties and weld quality.

This comprehensive testing regime ensures that only aluminium flanges meeting stringent quality standards proceed to packaging and shipment. The investment in quality verification protects both our reputation and customer interests by preventing field failures and ensuring reliable long-term performance.

Premium Packaging for Material Protection

When all tests are completed and aluminium flanges are ready for delivery, they are packed in high-quality packaging materials like wooden cases, pallets, or carton boxes which help prevent damage and avoid rust until aluminium alloy flanges reach their respective destinations. Protective wrapping prevents surface scratching during handling and transportation, while moisture barriers guard against atmospheric corrosion during extended storage or sea freight shipment.

The attention to packaging quality ensures that aluminium flanges arrive at customer facilities in pristine condition, ready for immediate installation without additional cleaning or surface preparation. Proper packaging also facilitates efficient handling, storage, and inventory management at customer locations, contributing to overall project efficiency.

Technical Support and Engineering Services

Our technical team provides comprehensive support to help customers select optimal aluminium flanges for specific applications. We offer guidance on alloy selection, pressure rating verification, gasket specification, and bolt torque requirements that ensure leak-tight connections and long-term reliability. Application engineering services help customers adapt aluminium pipe flange technology to unique requirements or challenging installations.

Joint design consultation addresses concerns about thermal expansion, galvanic corrosion when joining dissimilar metals, and proper isolation methods. Our experience across diverse industries enables sharing of insights and solutions that avoid common specification errors and achieve superior results.

Commitment to Excellence and Customer Satisfaction

Our commitment to manufacturing and supplying high-quality aluminium flanges meant to easily cater to various industrial applications in different domains reflects decades of dedication to customer success. The applications of these flanges can be traced to various industrial domains that are highly convenient for our customers and clients, demonstrating the versatility and reliability of our products.

Every aspect of our operations focuses on ensuring that customers receive aluminium flanges meeting their specifications and performing reliably throughout intended service life. This unwavering commitment to excellence has earned recognition as a preferred supplier among engineering firms, contractors, and industrial end-users across diverse sectors.

Contact Arham Alloys today to discuss your aluminium flanges requirements and discover how our comprehensive product range, technical expertise, and customer-focused service can contribute to the success of your piping system projects and industrial operations.

Product Usage & Application:-

- Truck And Marine Components

- Railroad Cars

- Furniture

- Tank Fittings

- Electricity & Energy Appliances

- Trusses

- Bridges

- Cranes

- Milk churns

FAQs

1: What Do Aluminium Flanges Manufacturers and Exporters Do?

Aluminium flanges manufacturers and exporters specialize in producing and supplying high-quality aluminium flanges used to connect pipes, valves, pumps, and other equipment in piping systems. These companies handle everything from raw material selection to precision machining, finishing, inspection, and global distribution.

Reliable manufacturers follow international standards for material composition, dimensional accuracy, and mechanical performance. Exporters ensure compliance with international packaging, documentation, and shipping norms, making aluminium flanges accessible to industries worldwide such as oil & gas, marine, construction, and chemical processing.

2.What Is an Aluminium Pipe Flange and How Does It Work?

Understanding the Aluminium Pipe Flange

An aluminium pipe flange is a mechanical component used to join sections of pipe or connect pipes to other equipment. It typically consists of a flat, circular disc with bolt holes that allow secure fastening.

Aluminium flanges work by creating a stable and leak-proof joint when bolted together with a gasket in between. The lightweight nature of aluminium makes installation easier while still providing strength and corrosion resistance.

3: What Are the Key Aluminium Flange Advantages?

Why Industries Prefer Aluminium Flanges

There are several important aluminium flange advantages:

-

Lightweight – Easier handling and reduced structural load

-

Corrosion resistance – Ideal for marine and chemical environments

-

Good thermal conductivity – Useful in heat exchange systems

-

Non-magnetic properties – Suitable for specialized electrical environments

-

Cost-effective maintenance – Less need for protective coatings

These aluminium flange advantages make them a strong alternative to heavier steel options in many applications.

4: What Are the Common Aluminium Flange Uses Across Industries?

Industrial Aluminium Flange Uses

Typical aluminium flange uses include:

-

Marine piping systems

-

Water treatment plants

-

HVAC installations

-

Food processing pipelines

-

Chemical handling systems

-

Automotive fluid lines

Because of their corrosion resistance and strength-to-weight ratio, aluminium flanges are widely chosen where durability and weight reduction are critical.

5: What Types of Aluminium Flanges Are Available?

Manufacturers produce various aluminium flanges to meet system requirements:

-

Slip-on flanges

-

Weld neck flanges

-

Blind flanges

-

Socket weld flanges

-

Threaded flanges

-

Lap joint flanges

Each type serves different pressure ratings, installation methods, and maintenance needs.

6: How Do Aluminium Flanges Manufacturers Ensure Product Quality?

Leading aluminium flanges manufacturers use advanced production facilities and strict quality control procedures. The process begins with carefully selected raw materials that meet international composition standards. Controlled manufacturing operations ensure accurate dimensions and mechanical properties.

At Arham Alloys, state-of-the-art production systems and stringent quality assurance protocols are followed. From raw material inspection to final testing, each stage ensures reliable aluminium flanges that perform consistently in demanding environments.

7: What Standards Do Aluminium Pipe Flanges Follow?

An aluminium pipe flange must comply with global standards such as:

-

ASME

-

ANSI

-

DIN

-

EN

-

ISO

These standards define dimensions, pressure ratings, and material specifications, ensuring that aluminium flanges from different manufacturers remain interchangeable and safe.

8: How Do Aluminium Flanges Compare to Steel Flanges?

While steel flanges are stronger under extremely high pressures, aluminium flange advantages make them preferable for many industries:

-

Lower weight reduces transportation and installation costs

-

Better resistance to atmospheric corrosion

-

Easier machining and fabrication

-

Lower long-term maintenance

Thus, aluminium flanges are often selected where moderate pressure and corrosion resistance are key requirements.

9: What Should You Look for in Aluminium Flanges Exporters?

When selecting exporters of aluminium flanges, consider:

-

Compliance with international standards

-

Quality certifications

-

Advanced manufacturing capability

-

Reliable packaging and logistics

-

Consistent material traceability

Experienced exporters ensure that aluminium pipe flange products reach global clients without damage and with proper documentation.

10: Why Choose Arham Alloys for Aluminium Flanges?

Arham Alloys combines advanced production technology with strict quality protocols. The company uses carefully selected raw materials and controlled manufacturing processes to achieve precise dimensions and reliable mechanical performance.

Their expertise in delivering materials in different processing states demonstrates strong metallurgical knowledge and manufacturing precision. With a commitment to consistency, customization, and global supply capability, Arham Alloys stands out among aluminium flanges manufacturers and exporters.

We Export To :

Kazakhstan, Algiers, Johannesburg, Pretoria, Dakar, Ghana, Uganda, Mozambique, Iraq, Subra al-Haymah, Australia, Yaoundé, South Africa, Saudi Arabia, Kampala, Benin, Ethiopa, Kuwait, Luanda, Abu Dhabi, Peru, Sudan, Colombia, Nairobi, Turkey, Russia, Khartoum, Kano, UAE, Bahrain, Cape Town, Trinidad and Tobago, Dar es Salaam, Nigeria, Antananarivo, Tripoli, Addis Ababa, London, Douala, Lebanon, Tunisia, Ouagadougou, Mogadishu, Harare, Mbuji-Mayi, Qatar, Zaria, Soweto, Omdurman, Angola, Alexandria, Dubai, Yemen, Casablanca, Africa, Oman, Giza, Kinshasa, Bamako, UK, Houston, Accra, Algeria, Argentina, Cairo, Chine, Kolwezi, Hong Kong, Abidjan, Vietnam, Port Elizabeth, Maputo, Maiduguri, Canada, Port Harcourt, Singapore, Egypt, Venezuela, Freetown, Ibadan, Iran, Fez, Malaysia, Mexico, Cameroon, New York, Indonesia, Italy, Azerbaijan, Israel, Conakry, Brazil, Democratic Republic of the Congo, New Zealand, Morocco, Jordan, United States, Thailand (Bangkok), Cyprus, Sri Lanka, Rabat, Bulawayo, Kaduna, Durban, Colombo, Germany, Lubumbashi, Lagos, Brazzaville.

We Supply To :

Tripura, Ahmedabad, Kolkata, Lucknow, Andhra Pradesh, Pune, Ambala, Maiduguri, Buxar, Puducherry, Karnataka, Maharashtra, Bhiwadi, Surat, Mizoram, Manipur, Delhi, Bangalore, Kerala, Ballia, Jamalpur, Chennai, Jaipur, Hyderabad, Indore, Patna, Agra, West Bangal, Ranchi, Durg, Bilaspur, Raipur, Satpura, Malwa, Kanpur, Dehradun etc.