When pipelines fail, they don’t just leak — they shut down plants, delay projects, and cost millions. And more often than not, the issue starts at the joints. That’s where carbon steel flanges come in.

These components might look simple, but in real-world operations — refineries, power plants, chemical units — the wrong flange choice can mean downtime, safety hazards, or pressure failures. So the real question isn’t “What is a flange?”

It’s “Which carbon steel flange is right for my pressure, temperature, and application?”

Let’s break it down properly.

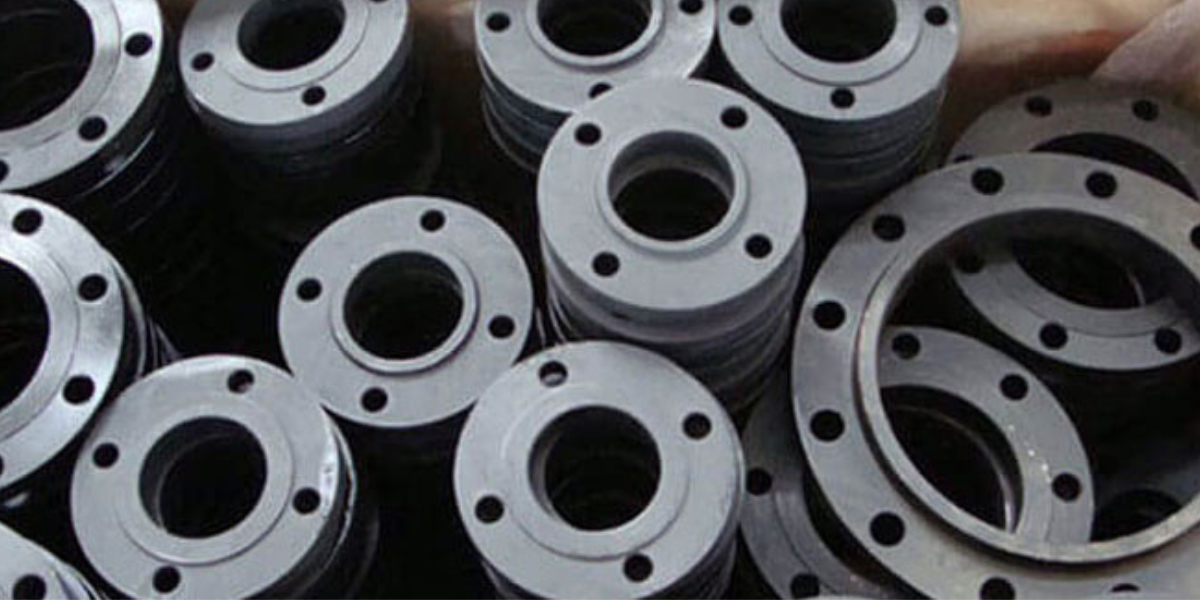

What Are Carbon Steel Flanges?

Carbon steel flanges are forged or machined components used to connect pipes, valves, pumps, and equipment to form a secure piping system. They allow easy assembly, maintenance, and inspection.

Why carbon steel?

- High strength under pressure

- Excellent durability

- Cost-effective for industrial use

- Suitable for high-temperature environments

From fabrication shops to offshore rigs, carbon steel flanges for oil and gas systems are industry standards for one reason: they handle stress like a pro.

Industrial Flange Types: Understanding the Basics

Before we dive into specific models, let’s understand why industrial flange types exist in so many variations.

Every piping system deals with different:

- Pressure loads

- Temperature ranges

- Fluid types

- Installation conditions

No single flange fits all. That’s why we have multiple types — each engineered for a specific job.

Weld Neck Carbon Steel Flange – The High-Pressure Champion

If you’ve worked on high-pressure steam or hydrocarbon lines, you’ve probably relied on a weld neck carbon steel flange.

Why it stands out:

- Long tapered hub distributes stress evenly

- Butt-welded to pipe for strong structural integrity

- Ideal for high-pressure and high-temperature systems

This flange is the go-to for:

- Refineries

- Power plants

- Offshore pipelines

When failure is not an option, engineers choose weld neck. Period.

Slip On Carbon Steel Flange – Fast, Easy, Reliable

Need quicker alignment and easier installation? Enter the slip on carbon steel flange.

Key features:

- Pipe slips into flange bore

- Fillet weld inside and outside

- Lower installation cost than weld neck

Best suited for:

- Low to moderate pressure systems

- Water lines

- Fire protection pipelines

It’s not designed for extreme stress — but for general service, it’s efficient and economical.

Blind Carbon Steel Flange – The System Stopper

Want to terminate a pipeline or prepare for future expansion? A blind carbon steel flange seals the deal.

Why it’s critical:

- No bore — completely closes pipe end

- Handles high pressure loads

- Ideal for pressure testing

Used heavily in:

- Maintenance shutdowns

- Oil and gas process units

- Pressure vessel closures

Simple piece. Major responsibility.

Socket Weld Carbon Steel Flange – Built for Small Bore Strength

When working with small-diameter, high-pressure lines, the socket weld carbon steel flange is a smart choice.

What makes it special:

- Pipe inserts into socket before welding

- Strong fatigue resistance

- Reduces leakage risk

Common in:

- Hydraulic systems

- Chemical processing

- High-pressure small pipelines

Precision matters here — gap allowances during welding are critical to avoid stress cracking.

Threaded Carbon Steel Flange – When Welding Isn’t Possible

No welding setup? Hazardous environment? A threaded carbon steel flange solves the problem.

Why it’s used:

- Screws onto pipe threads

- Easy installation and removal

- Good for low-pressure services

Applications include:

- Utility services

- Compressed air systems

- Hazardous areas where welding sparks are risky

It’s convenient — but not meant for high vibration or pressure.

ASTM A105 Carbon Steel Flange – The Industry Standard

If you’ve reviewed flange specs, you’ve seen ASTM A105 carbon steel flange repeatedly.

Why ASTM A105 matters:

- Forged carbon steel material

- Excellent strength and toughness

- Suitable for ambient and higher temperatures

This grade is widely used for:

- Refineries

- Power generation

- Oil and gas pipelines

When someone says “standard carbon steel flange,” they usually mean ASTM A105.

Carbon Steel Flange Pressure Ratings Explained

Not all carbon steel flanges handle the same pressure. That’s where carbon steel flange pressure ratings come into play.

Common pressure classes:

- Class 150

- Class 300

- Class 600

- Class 900

- Class 1500

- Class 2500

Higher class = thicker flange + stronger bolts + better sealing.

Choosing the wrong pressure rating is one of the biggest installation mistakes — and one of the costliest.

Carbon Steel Flanges for Oil and Gas Applications

The oil and gas industry demands:

- High pressure resistance

- Corrosion tolerance

- Structural reliability

That’s why carbon steel flanges for oil and gas pipelines are typically weld neck or blind flanges made from ASTM A105.

They are used in:

- Drilling rigs

- Refinery units

- Offshore platforms

- Gas transmission lines

In these environments, flange failure isn’t an inconvenience — it’s a safety hazard.

Choosing the Right Carbon Steel Flange

Ask yourself:

- What’s the pressure class?

- What temperature will the system run at?

- Is welding possible?

- Do I need future disassembly?

Correct selection ensures:

✔ Leak-free performance

✔ Longer pipeline life

✔ Lower maintenance cost

Wrong selection? Expect downtime.

Installation Best Practices (From Field Experience)

From real job sites, here’s what actually matters:

- Always check flange face finish

- Use correct gasket material

- Tighten bolts in star pattern

- Verify alignment before welding

- Don’t reuse damaged bolts

These small steps separate a professional job from a failure waiting to happen.

Final Thoughts

Carbon steel flanges are the backbone of industrial piping. From weld neck carbon steel flange strength to blind carbon steel flange sealing capability, each type plays a specific role.

Understanding industrial flange types, material grades like ASTM A105 carbon steel flange, and correct carbon steel flange pressure ratings ensures safe and efficient operations.

Because in piping systems, the connection points matter more than the pipes themselves.

Frequently Asked Questions About Carbon Steel Flanges

1. What are carbon steel flanges used for?

Carbon steel flanges are used to connect pipes, valves, pumps, and pressure vessels in industrial piping systems. They provide strong, leak-resistant joints that can be assembled and disassembled for maintenance. These flanges are widely used in power plants, refineries, chemical processing units, and carbon steel flanges for oil and gas pipelines because they handle high pressure, temperature, and mechanical stress effectively.

2. Which type of carbon steel flange is best for high-pressure applications?

A weld neck carbon steel flange is considered the best option for high-pressure and high-temperature systems. Its long tapered hub reduces stress concentration at the base of the flange, and the butt-weld connection ensures superior strength. These are commonly used in steam lines, hydrocarbon processing, and critical industrial flange types in refineries.

3. What is the difference between a slip on carbon steel flange and a weld neck flange?

A slip on carbon steel flange slides over the pipe and is fillet welded, making it easier and cheaper to install. However, it offers less strength compared to a weld neck carbon steel flange, which is butt-welded and provides better fatigue resistance and pressure handling. Slip-on flanges are ideal for low to medium pressure, while weld neck flanges suit demanding services.

4. When should a blind carbon steel flange be used?

A blind carbon steel flange is used to seal the end of a piping system or pressure vessel opening. It is commonly installed during maintenance shutdowns, pressure testing, or future pipeline expansion. Because it has no bore, it can withstand high pressure and is frequently used in carbon steel flanges for oil and gas processing systems.

5. What are socket weld carbon steel flanges typically used for?

A socket weld carbon steel flange is used in small-diameter, high-pressure pipelines. The pipe fits into a recessed socket before welding, creating a strong, leak-resistant connection. These flanges are commonly used in hydraulic systems, chemical plants, and steam lines where precision and fatigue resistance are important.

6. Where are threaded carbon steel flanges preferred?

A threaded carbon steel flange is ideal in systems where welding is unsafe or impractical, such as hazardous environments or temporary installations. They are typically used in low-pressure applications like compressed air, water lines, and utility services. However, they are not recommended for high vibration or extreme pressure.

7. What is ASTM A105 carbon steel flange material?

An ASTM A105 carbon steel flange is made from forged carbon steel designed for high-temperature and ambient-temperature service. It offers excellent strength, impact resistance, and durability, making it one of the most commonly specified materials in refineries, power plants, and industrial flange types used globally.

8. How do carbon steel flange pressure ratings work?

Carbon steel flange pressure ratings indicate the maximum pressure a flange can withstand at specific temperatures. Common classes include 150, 300, 600, 900, 1500, and 2500. Higher classes mean thicker flanges, stronger bolting, and higher load capacity. Selecting the correct pressure class is essential to prevent leaks or mechanical failure.

9. Why are carbon steel flanges widely used in oil and gas industries?

Carbon steel flanges for oil and gas are preferred due to their strength, cost-effectiveness, and ability to withstand high pressure and temperature conditions. They are used in drilling platforms, refineries, gas processing plants, and transmission pipelines where reliability and safety are critical.

10. How do you choose the right carbon steel flange type?

Choosing the right carbon steel flanges depends on pressure rating, temperature, pipe size, fluid type, and installation method. For high stress, use weld neck; for easy installation, slip-on; for sealing ends, blind; for small high-pressure lines, socket weld; and for non-welded systems, threaded flanges. Proper selection ensures longer system life and fewer maintenance issues.